Description

Applications & Benefits

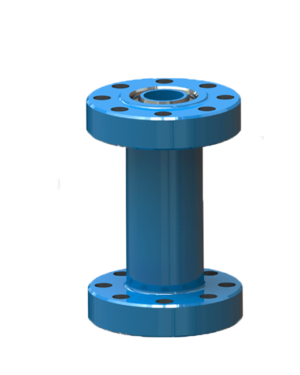

deenpu supplies drilling spools that are in line with API specification 6A. Drilling spools allow the smooth circulation of mud during drilling operations and usually have the same nominal top and bottom end connections. Side outlet may differ from each other. Top, bottom and side end connections can be hub end or flanged. Tasman have a substantial inventory of Drilling and Diverter Spools which are manufactured with a variety of end and outlet configurations based on customer needs.

Key Features

Flanged, studded, and hubbed ends available, in any combination

Manufactured for any combination of size and pressure ratings

Drilling and Diverter Spools designed to minimize length while allowing sufficient clearance for wrenches or clamps, unless otherwise specified by the customer

Available for general service and sour service in compliance with any temperature rating and material requirements specified in API specification 6A

Available with Stainless Steel 316L or Inconel 625 corrosion resistant alloy ring grooves

Tap-end studs and nuts are normally provided with studded end connections

Availability Specification

| Working pressure | 2000PSI-20000PSI |

| Working medium | oil,natural gas,mud |

| Working temperature | -46ºC-121ºC(L-U) |

| Material class | AA -HH |

| Specification class | PSL1-PSL4 |

| Performance class | PR1-PR2 |

Our company has been in the oil & gas drilling equipment industry for over more years, We are here to serve all your drilling equipment needs.

Our company has been in the oil & gas drilling equipment industry for over more years, We are here to serve all your drilling equipment needs.

Reviews

There are no reviews yet.