Description

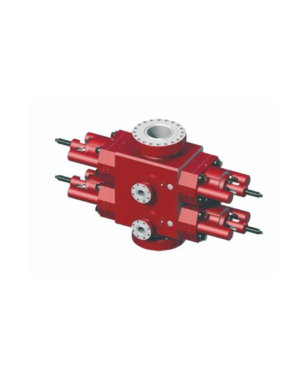

BOP Rams

DEENPU is a fully integrated API manufacturing OEM with the capability of custom designing and manufacturing any material to meet your specifications. With the ever-changing well designs and the ability to drill longer and deeper wells, we have designed and proven durable rams that enhance the features of our BOP equipment. BOP Rams, or ram blocks, consist of four common types: pipe, blind, variable bore, shear and blind shear; and are offered for mid to large bore, high pressure BOPs.

Rams Include the Following Features:

Pipe rams are self-feeding and incorporate a large reservoir of packer rubber to ensure a long-lasting seal under all conditions.

Ram packers lock into place and are not dislodged by well flow.

All BOP Products pipe rams are suitable for H2S service per NACE MR-01-75.

seals are standard for all Series 700 BOP rams from 7-1/16” through 26-3/4” sizes.

BOPRAM 350 packers and top seals are available for high temperature

service and for service in which concentrations of H2S are expected

SBR’s, DS, and ISR Rams Include the Following Features:

Large frontal area on the blade face seal reduces pressure on the rubber and increases service life.

SBRs can cut pipe numerous times without damage to the cutting edge.

The single-piece body incorporates an integrated cutting edge.

BOP Products top seals are standard for all U BOP shearing blind rams through 18-3/4″.

H2S SBRs are available for critical service applications and include a blade material of hardened high alloy suitable for H25 service.

shearing blind ram has a single-piece body with an integrated cutting edge.

Our company has been in the oil & gas drilling equipment industry for over more years, We are here to serve all your drilling equipment needs.

Our company has been in the oil & gas drilling equipment industry for over more years, We are here to serve all your drilling equipment needs.

Reviews

There are no reviews yet.