Description

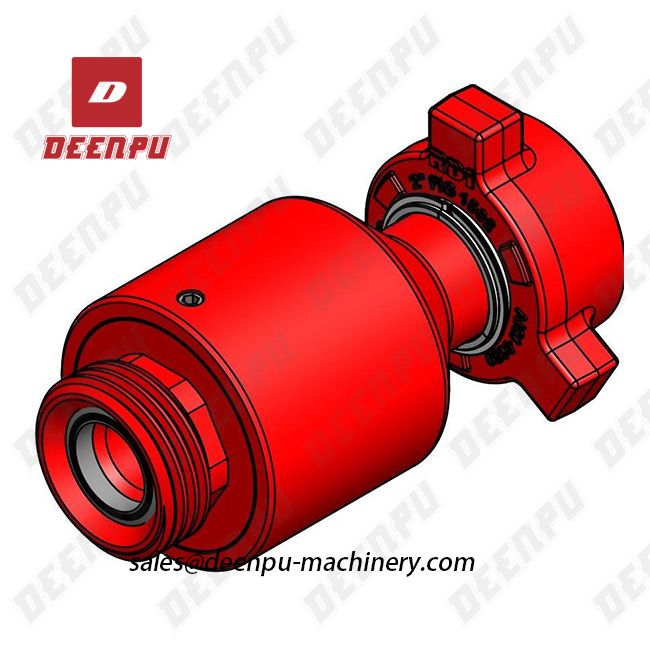

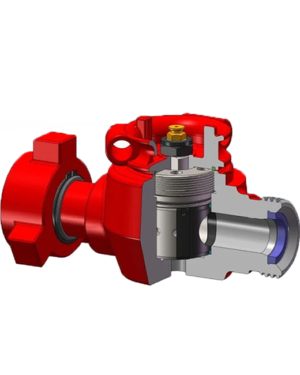

Flapper Check Valve – Clapper Check Valve

Flapper Check Valves – Clapper check valves are designed for well service applications such as fracturing, cementing and acidizing. The flapper check valve is placed in the treating line to allow flow to the well but isolates and back flow to go upstream in the valve. This provides a safety device at various locations in the flow line and assure that pressure and fluid can not backup into the manifold or into pumps.

The check valves provided by DEENPU are available in size ranges in 2″, 3″ and 4″, in pressure ranges from 6,000psi to 20,000psi with hammer union end connections.

Available Specification:

| Nomal Size, in | Working Pressure, psi | End Connection | Flow Condition |

|---|---|---|---|

| 1 1/2 | 15,000 | Fig1502 M X F | H2S |

| 2 | 15,000 | Fig1502 F X M | Standard |

| 2 | 15,000 | Fig1502 M X F | H2S |

| 2 | 20,000 | Fig2002 F X M | Stardard |

| 3 | 6,000 | Fig602 F X M | Stardard |

| 3 | 6,000 | Fig602 M X F | H2S |

| 3 | 6,000 | Fig602 F X F | Stardard |

| 3 | 15,000 | Fig1502 F X M | Stardard |

| 3 | 15,000 | Fig1502 M X F | H2S |

| 3 | 20,000 | Fig2002 F X M | Stardard |

| 4 | 6,000 | Fig602 F X M | Stardard |

| 4 | 10,000 | Fig1002 F X M | Stardard |

| 4 | 15,000 | Fig1502 F X M | Stardard |

| 4 | 15,000 | Fig1502 M X F | H2S |

Our company has been in the oil & gas drilling equipment industry for over more years, We are here to serve all your drilling equipment needs.

Our company has been in the oil & gas drilling equipment industry for over more years, We are here to serve all your drilling equipment needs.

Reviews

There are no reviews yet.