Description

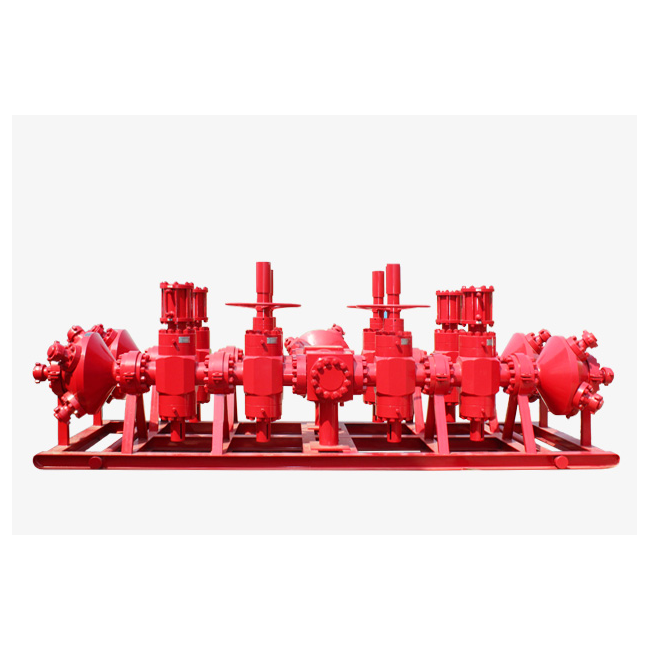

choke and kill manifold

Choke manifold is necessary device to control the well kick successfully and execute the pressure control technology on oil/gas well in the course of drilling, as it is,the device is adopted to execute new drilling-well’s technique of balance pressure,which can avoid pollution of oil-layer,improve the speed of drilling and control blowout effectively.

Kill Manifold consists of check valves, gate valves, pressure gauges and line pipes. One end of the kill manifold is connected to drilling spool and the other to pump.Kill manifold is necessary equipment in well-control system to pump drilling fluid into well barrel or inject the water into wellhead.

Our company’s choke and kill manifold falls into five class: 14MPa, 21MPa, 35MPa, 70MPa and 105MPa. Also, We can design according to customer demand.

Used to control flow and pressure during testing

Special five-valve module (gate valve)

Double-bean design: one (1) positive choke valve with a pressure relief valve on one side and one (1) manual choke valve on the other side.

Full bore and two-way metal seal

Choke bean features hard alloy inside, delivering high resistance to erosion and corrosion.

| Bore | 2 1/16″~ 4 1/16″ |

| Working Pressure | 5,000~15,000psi |

| Temperature Level | L, P, U |

| Material Grade | DD, EE, FF, HH |

| Manufacturing Level | PSL2, PSL3, PSL3G, PSL4 |

| Performance Level | PR1, PR2 |

| Standards | API SPEC 6A , API SPEC 16C |

Our company has been in the oil & gas drilling equipment industry for over more years, We are here to serve all your drilling equipment needs.

Our company has been in the oil & gas drilling equipment industry for over more years, We are here to serve all your drilling equipment needs.

Reviews

There are no reviews yet.