Our annular blowout preventer packing elements are molded from proprietary rubber formulation and geometrically designed for advanced fatigue and stripping performance in oilfield applications.

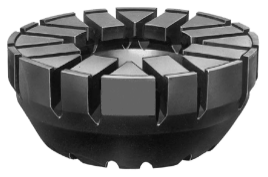

Annular Bop Packing Elements

Our annular blowout preventer packing elements are molded from proprietary rubber formulation and geometrically designed for advanced fatigue and stripping performance in oilfield applications.

Spare packing elements are tested to stringent engineering and quality requirements, based on API 16A standards for factory acceptance testing of spare packing elements.

Spare packing elements are tested to stringent engineering and quality requirements, based on API 16A standards for factory acceptance testing of spare packing elements.

this includes both low and high pressure complete shutoff tests, as well as low and high pressure pipe mandrel tests to maximum rated pressures and drifting testing.

Available of size:

| BOP Size Working Pressure | BOP Type | Match with | |

| Oversea | China | ||

| 7 1/16″-5,000 psi | bolted cover models | Yes | Yes |

| 9″-5,000 psi | bolted cover models | Yes | Yes |

| 11″-3,000 psi | bolted cover models | Yes | Yes |

| 11″-5,000 psi | bolted cover models | Yes | Yes |

| 11″-10,000 psi | bolted cover models | Yes | Yes |

| 13 5/8″-5,000 psi | bolted cover models | Yes | Yes |

| 13 5/8″-10,000 psi | Wedge cover models | Yes | Yes |

| BOP Size and Working Pressure | BOP Type | Matched BOP Manufacturer | |

| Foreign | Domestic | ||

| 9″-5,000 psi | GK | Yes | Yes |

| 11″ 5000psi | GK | Yes | Yes |

| 11″-10,000 psi | GX | Yes | Yes |

| 13 5/8″-5,000 psi | GK | Yes | Yes |

| 13 5/8″-10,000/15,000 psi | GX | Yes | Yes |

| 16 3/4″-5,000 psi | GK | Yes | Yes |

| 21 1/4″-2,000psi | MSP | Yes | Yes |

| 29 1/2″-500 psi | MSP | Yes | Yes |

FeatureS / BenefitS

Materials expertise

Extensive materials research and development for elastomers and plastics

Experience with a wide range of material to provide optimal solutions

Complete pre-production material and process validation

Solutions for the most challenging environments

Compatible with most major annular Bops

Elements may be provided to API 16A factory acceptance test requirements at 100% working pressure on pipe and 50% pressure closed on open hole

includes Seal of authenticity and test results in documentation package

Extensive fluid immersion and temperature testing on each formula

Rigorous analysis and testing

- Product testing lab enables API 16A requirement testing on Bops, ram packers and more

- Material test capabilities across a broad spectrum of gas and liquids

- Thermal cycling lab for product function testing

- Compound development capabilities for extreme applications

Our company has been in the oil & gas drilling equipment industry for over more years, We are here to serve all your drilling equipment needs.

Our company has been in the oil & gas drilling equipment industry for over more years, We are here to serve all your drilling equipment needs.