Description

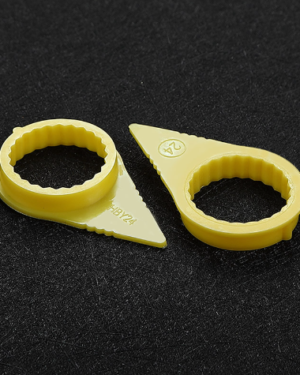

Casing Centralizer

Casing centralizer meaning is a mechanical device or cementing tool. It is an integral part of the cementing process.

It is installed outside the casing string secured around the casing at various locations to keep the casing from contacting the well bore walls, acts as a righting sleeve in the well bore.

They provide the mechanism that centers the casing in the hole and allows uniform cement flow around the casing to help protect it at all points.

Casing centralizer as a cementing tool is applied in vertical, deviated and horizontal wells to centralize casing for improving the cementing quality.

As a result of casing centralization, a continuous annular clearance around the casing allows cement to completely seal the casing to the borehole wall.

The cement could be concreted firmed between casing and borehole wall.It can be installed on casing joint or any position working with stop collar for centralizing.

All models offer ample clearance for fluid passage and are extra effective in centering the casing, even in highly deviated holes and improve cement flow by reducing the effects of channeling.

Several styles of centralizers are available for matching different well specifications and hole sizes, including turbulence generating designs that help clean the annuls and distribute the cement more evenly and uniformly.

Casing Centralizer Types

There are various types of Casing Centralizers used in the oil and gas industry, but these are the 2 primary types of centralizers:bow spring centralizers and rigid centralizers.

(If As per action form, it can be divided into Bow Spring casing centralizer, rigid casing centralizer and semi-rigid centralizer.)

Bow-Spring Centralizer

This type of centralizer is a bow-shaped metal strip used to centralize the casing in a borehole so as to improve the efficiency of cementing.

Bow spring centralizers are slightly larger in diameter than the well bore, so they become slightly compressed when inserted into the well bore. They are often used in vertical wells as there is near zero deviance in annular space about the tool.

(As per structure of the righting strip,the elastic centralizer can be divided into single bow centralizer and a double bow centralizer.)

Rigid Centralizer

This type of centralizer is built using steel or cast iron and works well with the deviated wellbores. It is not as effective as bow-spring centralizers.

Rigid centralizers are slightly smaller than the well bore.

They are more commonly used in deviated or horizontal well bores where the weight of the casing string would cause a bow spring centralizer to experience eccentric compression which could jeopardize the seal.

(The rigid casing centralizer can be divided into ordinary rigid centralizer and roller rigid centralizer.)

Our company has been in the oil & gas drilling equipment industry for over more years, We are here to serve all your drilling equipment needs.

Our company has been in the oil & gas drilling equipment industry for over more years, We are here to serve all your drilling equipment needs.

Reviews

There are no reviews yet.